The Royal Navy (RN) is deeply ingrained in the United Kingdom’s (UK) culture and history, reflecting it island status and many centuries of maritime tradition. The inherent mobility associated with the nature of naval operations, enables the RN to protect the UK’s interests through the provision of security at sea. It aims to prevent conflict, promote partnerships and alliances, and protect the UK’s economy.

The modern RN is a versatile force, able to operate across considerable breadth, whether through the provision of humanitarian aid, through a range of effects to full scale warfighting. To ensure future freedom of access around the world and hence the ability to maintain these operations, the UK Ministry of Defence, the Royal Navy and Royal Fleet Auxiliary (RFA) must meet, or mitigate the effects of, the ever changing global regulatory landscape. An essential element of this is effectively manging the Fleet’s emissions.

The Strategic Defence and Security Review (SDSR) of 2015 emphasised the UK Government’s commitment to a strong maritime force. Underwater presence is maintained through four strategic missile carrying submarines and seven nuclear powered attack submarines. The SDSR also committed to two Queen Elizabeth Class (QEC) aircraft carriers, the largest ships ever to have served with the Royal Navy and to the maintenance of an amphibious capability. The backbone of the fleet, the destroyer and frigate flotillas, are set to modernise with the hugely successful Type 23 frigates being superseded by an even more capable replacement Type 26 frigate, which will incorporate world class anti-submarine warfare capability and for the first time the flexibility of modular mission bay. In addition, the UK is conducting pre-concept design work on a new class of light, general purpose frigate known as the Type 31, which is being designed with exportability in mind. The myriad of smaller vessels and supporting shipping provided by the Royal Fleet Auxiliary are no less significant, and add critical niche capabilities to a balanced fleet.

HMS Queen Elizabeth to be commissioned in summer 2017.

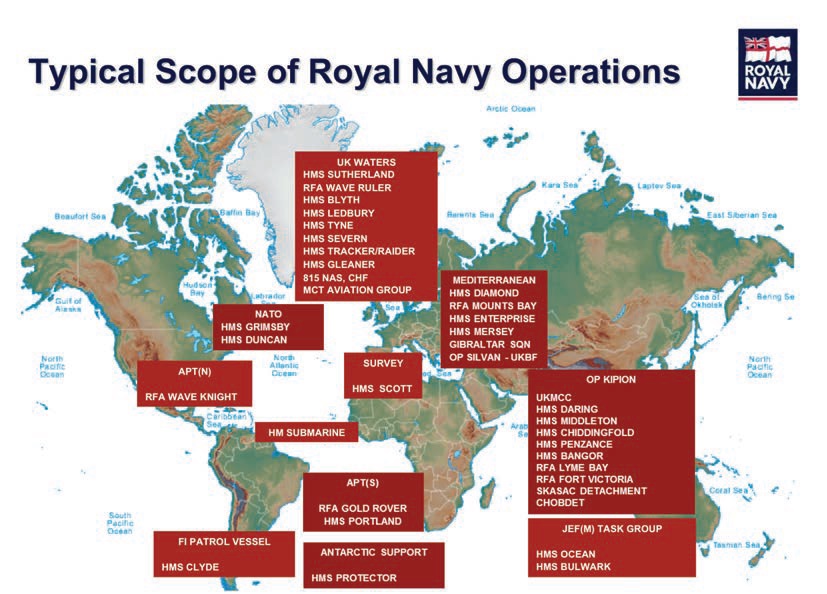

The Royal Navy maintains a significant global presence 24 hours a day throughout the year. A snapshot of fleet operations at any one time will indicate a presence in the South Atlantic, Caribbean, Mediterranean, Indian Ocean and the Gulf. It maintains Continuous At Sea Deterrence through the four Vanguard Class ballistic missile carrying submarines, which has been a continuous operation since 1967. In addition to those standing tasks, the Royal Navy regularly deploys Task Groups, an essential element of the international defence engagement strategy, which underpins broader UK influence. These factors are significant because the Royal Navy operates globally, and frequently operates in areas currently or planning to enact emission control areas (E.g. IMO ECAs). These include the North Sea, Baltic, English Channel, US Coast, and Mediterranean. Furthermore, the scale and disposition of regulated waters will grow, potentially exponentially. A failure to address emissions may, therefore impede global access.

While this current and new maritime force reflects a lower number of hulls than historically, operational tempo for individual platforms is high, driving energy demands and hence emissions. Equally RN and RFA platforms have

seen significant leaps in capability when compared to older platforms. This equates to larger, more flexible platforms and with the introduction of the QEC class at 65,000 tonnes each, the fleet’s overall displacement is set to grow further. While these new platforms are inherently more efficient, sheer size and tempo demands drive an expected trend in growing energy use over the next decade, with a corresponding impact of the fleet’s emissions.

In a rapidly changing world there are tangible challenges and opportunities for the RN to adapt to and benefit from. These including an appropriate focus on preservation on the environment of the world we serve to protect, through careful consideration of evolving emissions regulations. Whilst government vessels are currently exempt from much of the international environmental legislation & regulation (e.g. IMO MARPOL), the RN aims for compliance as a result of the UK Government’s policy to behave as good world citizens. In the operation of today’s and tomorrow’s fleet, the RN must meet and contribute to UK Government policies & targets, ensure that in the future it can continue to operate globally and access future operational access, and adapt to operating in emission sensitive areas. UK Government Departments, including the Ministry of defence, are therefore bound to comply with environmental targets from a macro perspective ‘where practicable’, but also constrained operationally, and subject to cost impacts of local emissions regulations in other countries for which crown immunity could never be applied.

Notwithstanding the obligation to meet regulatory emissions standards, there are other compelling arguments to behave as good citizens. Local populations and their attitudes to the environment have changed over the last two decades, and when warships steam in and out of harbour with clearly visible black funnel gases, the reputation of the vessel owner and associated nation can be tarnished. Meeting emissions regulations ease access into new areas; these could include a future need to patrol ice free areas of artic. Finally if emission reductions are achieved through reduced platform energy consumption this offers the RN and individual ship commanders an opportunity to enhance capability advantage through improved range, endurance and time on station.

Specific emission challenges evolve, but 3 key areas are currently regulated at an international level:

Compliance, therefore, creates specific technical challenges for the UK Ministry of Defence. These include matching evolving changes in emissions policy and regulation, to transient and evolving emission control technologies, onto platforms with operating lives that typically exceed 30 years.

Emissions control technologies developed for commercial maritime use are often designed with less focus on space and weight constraints that are found on naval platforms. Retro-fitting of these options, therefore, is often unfeasible within naval space and weight limitations, with solutions also having the potential to aggravate other competing requirements in areas such as platform survivability and machinery availability. In addition, the consumables required to support the through life management of, for example, Selective Catalytic Reduction (SCR) would necessitate a wholesale change to the modus operandi of naval task-groups through the necessity to provision liquid or pellet based urea in bulk. Finally the failure of such systems must not affect operational capability or availability, and so redundancy in terms of being able to by-pass such systems is essential, but again adding to the weight, space and cost of integration.

The RN has investigated and fitted numerous hydrodynamic features to minimise drag. Newer platform such as Type 45, Type 26 and QEC have seen these integrated at design, but older platform such as Type23 have also seen mid-life modifications to incorporate their benefits. These features have included stern flap (wedges), self-polishing anti-fouling coatings on the hull and propeller blades, Propeller hull form optimised better match to economic speeds and improved propeller designs balancing the needs of low noise and efficiency. Other features which are

currently being investigated include changes to appendages, Intelligent trim systems and propeller boss cap fins.

Within the platform’s internal systems, the RN is starting to benefit from the growing level of data generated by the numerous sensor connected to Platform Management Systems (PMS). On newer platforms such as Type 45, this has the potential to allow platform efficiency to be assessed in near real time. Tools are under development that provides guidance to crews on the current hull state, and the optimal speed, trim and machinery configuration for a given mission, based on the current sea and weather conditions. In additional energy reduction in areas such as lighting (LED lamps), heating (better control of HVAC and better insulation) and sharing of waste heat in hot water systems bring not reductions in energy demand but second order benefits on overall cooling system demand through reduced wild heat. One example on Type 26 will be the heating of main gearing lub-oil through the use waste heat from the diesel generators, so saving an estimated £4million throughout the life of the class. Another, smaller, example is the development of a non-petrol burning outboard motor for small boats. If successful this will allow UK ships to reduce the number of different types of fuels carried, thereby reducing overall fuel usage through the supply chain.

Both the RN and RFA fleets have already seen the benefits of adopting fully Integrated Full Electric Propulsion (IFEP) systems on efficiency. This approach enables operators, when operating conditions allow, minimise prime mover operation and to utilise optimum prime movers nearer to their ideal operating points. This not only optimises fuel economy and hence net emissions, but also significant reduces support burden through lower overall prime mover operating hours.

The introduction of advanced electrical propulsion has spurred the development of a Real Time Digital Simulation and Power Hardware in the Loop facility at the Power Network Distribution Centre, which is part of the University of Strathclyde. With an overall capacity of 540 KVA, it will be the most capable set up in Europe and when it is completed in March 2017. Its introduction will allow the MoD to accurately model ship electrical systems and

their responses to a wide range of scenarios and the ability to adjust parameters to fine tune configuration. The net result should be that future electrical systems are more capable, stable, and predictable and optimised such that overall fuel usage and carbon emissions are reduced.

The Type 45 intercooled and regenerative complex cycle Rolls Royce WR21 engines are unparalleled in thermodynamic performance amongst marine gas turbines, a by-product of the 1980’s Marine Engineering Development Programme. But fuel efficiency gains are not the preserve of new design; over the past 15 years there has been a relentless focus on incremental performance gains of in-service platforms.

Looking at the make-up of the fleet, the shape of prime mover operation has shifted; Three decades ago the major proportion of fuel was burnt in gas turbines, at that time and currently which remain exempt from IMO regulation. But this is no longer the case; the paucity of appropriately sized marine gas turbines, increased power density and reliability of medium and high speed diesels, the flexibility of the RN/RFAs All electric architectures, and the necessity to reduce the dependency on fossil fuels has driven prime mover operation in the favour of the diesel

engine; increasing the importance of meeting emissions standards.

But technological solutions are just a part of the solution to minimising fuel burn; behavioural changes are essential, and these have been achieved through amendments to fuel allocations, training, and incentivisation programmes, such as the proposed ‘Green Duster’ award, which aim to reward the best behaving ships.

IMO’s MARPOL NOx regulations are applicable to new vessels and to vessels undergoing such significant modification where prime movers are replaced with a different type of engine. The UK Ministry of Defence is aiming to be fully compliant on the new Type 26 frigates where weight, space, urea storage and electrical margins have been included to support a notional SCR system coupled to its MTU4000 20V diesel generators. The Type 23 is also undergoing a major capability upgrade programme, which includes the Power Generation Machinery Upgrade (PGMU) where the long serving Paxman Valentas will be replaced with MTU units.

The reliance on old methods of delivering military effect is always under examination, and the revolution in unmanned and autonomous systems potentially assists the downward trend in emissions. The future of Mine Counter-Measures (MCM) and Hydrography will be delivered using a combination of unmanned surface, sub-surface and aerial vehicles, all of which reduce reliance on fossil fuels dramatically per unit of capability delivered as well as increasing the ability to deploy these systems from a range of warships and commercial vessels. The Mine Countermeasures and Hydrographic Capability (MHC) project is currently in the assessment phase in collaboration with the French Navy, and is heavily reliant on the demonstration of such technology. Similarly, the future of Anti-Submarine Warfare (ASW ) could be delivered using Unmanned Underwater Vehicles and Unmanned Surface Vessels (USV ) with corresponding reductions in fuel burn, and better data processing and sharing will multiply efforts in international task groups. Using assets to deliver more effect concurrently will be assisted through the application of modular capability solutions, which in combination with vessels such as the Type 26 will enable more to be delivered with less. And finally, better synthetic training in the future will obviate the need to sail large groups of ships to train Command and Control; Navigation is a quick win, but thereafter the full gamut of collective training, thirsty in its demands for fossil fuels if conducted in ships, should be tested against the capability of modern synthetic training environments.

The UK Ministry of Defence and the Royal Navy is constantly investing in a range of new and innovative measures to reduce both energy consumption and emissions. The adaptation of commercially available solutions presents huge opportunities, but we are also exploring our own research, often in partnership with other nations, to meet our specific needs. Emissions and environmental legislation is attracting significant focus and may constrain the utility of existing military solutions. Other methods of delivering the same effect will be required in the future.Whilst IMO Tier III and subsequent regulation is being addressed, there remains risk ahead; predicting regulatory constraints within the life cycle loop of warship acquisition cycles will always be testing, and as a result careful consideration of the likely regulation ahead is made during the acquisition cycle for new equipment with the UK MOD.

En 1795 George III creó la Oficina Hidrográfica británica, con el objetivo de producir información de utilidad náutica, ...

FOST se Ha convertido con el pasar de los años, en un referente y en el estándar a alcanzar por las unidades a flote de la Organización del Tratado Atlántico Norte (OTAN) antes de que sean desplegadas a sus respectivas áreas de operaciones. La presencia de oficiales chilenos en FOST, ha logrado transmitir esta impronta a las unidades de nuestra Marina, lo que ha perfeccionado nuestro entrenamiento institucional y contribuido a aumentar la calidad de la conducción de operaciones a nivel conjunto y combinado.

Después de varios años de estudios, la nueva generación de fragatas especialistas en la guerra antisubmarina de la Royal Navy, las Type 26 Global Combat Ships están en construcción. La primera Type 26 Batch 1, comenzó su fabricación el 20 de julio de 2017, en los astilleros de BAE Systems Govan y Scotstoun en el Rio Clyde, de Glasgow, Reino Unido, lo que marcó el inicio de la renovación de las fragatas de la Royal Navy.

El autor presenta en forma sistémica las variables del campo táctico, y la forma como su estudio y análisis vía simulaciones puede llevar a explotar tácticamente el medio en que se realizan las operaciones. También expone la forma en que la Armada Real Británica ha asumido este desafío.

Versión PDF

Año CXXXX, Volumen 143, Número 1009

Noviembre - Diciembre 2025

Inicie sesión con su cuenta de suscriptor para comentar.-